silicon carbide poda

Product Description

Izvo zvemuviri zvimiro zvesilicon carbide poda zvinosanganisira kusimba kwepamusoro, kupfeka kuramba, corrosion resistance, high thermal conductivity, yakanakisa magetsi ekudzivirira uye yakafara thermal shock performance.Zvinhu izvi zvinoita kuti SIC powder ive chinhu chakakodzera, chinogona kushandiswa zvakanyanya munzvimbo dzakanyanyisa dzakadai sekushisa kwepamusoro, kudzvinyirira, simba guru uye nemwaranzi yakasimba.Silicon carbide poda ine huwandu hwakawanda hwekushandisa, kunyanya kusanganisira ceramics, semiconductors, simba idzva uye mamwe minda.Mumunda weceramics, silicon carbide poda inogona kushandiswa kugadzira yakakwirira-inoita zvedongo zvinhu, zvakadai sepamusoro-tembiricha zvedongo mbiya, ceramic bearings, etc. Mumunda we semiconductor, silicon carbide powder inogona kushandiswa kugadzirira semiconductor zvishandiso, zvakadai. se diode, zvigadzirwa zvemagetsi, nezvimwewo. Mumunda wesimba idzva, silicon carbide powder inogona kushandiswa kugadzirira mafirimu e-anti-reflection yemasero ezuva kuti avandudze kushanduka kwesimba rezuva.

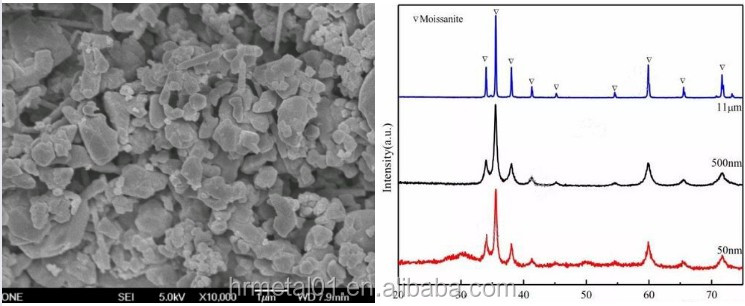

Tsanangudzo yezvinyorwa

| silicon carbide sic poda yakatarwa ye nonabrasive | ||||

| Type | Reference chemical composition (%) | Saizi(mm) | ||

| SiC | FC | Fe2O3 | ||

| TN98 | ≥98.00 | <1.00 | <0.50 | 50~0 |

| TN97 | ≥97.00 | <1.50 | <0.80 | 13~0 |

| TN95 | ≥95.00 | <2.50 | <1.00 | 10~0 |

| TN90 | ≥90.00 | <3.00 | <2.50 | 5~0 |

| TN88 | ≥88.00 | <3.50 | <3.00 | 0.5~0 |

| TN85 | ≥85.00 | <5.00 | <3.50 | 100F |

| TN60 | ≥60.00 | <12.00 | <3.50 | 200F |

| TN50 | ≥50.00 | <15.00 | <3.50 | 325F |

Quality control system

Huarui ine yakasimba yemhando manejimendi system.Isu tinoyedza zvigadzirwa zvedu kutanga mushure mekunge tapedza kugadzira kwedu, uye tinoyedza zvakare tisati tasvika kwese kutumirwa, kunyangwe sampuli.Uye kana uchida, tinoda kugamuchira wechitatu bato bvunzo.Ehe kana uchida, tinogona kukupa sampuro kwauri kuti uedze.

Hunhu hwedu hwechigadzirwa hunovimbiswa neSichuan Metallurgical Institute uye Guangzhou Institute of Metal Research.Kubatana kwenguva refu navo kunogona kuchengetedza nguva yakawanda yekuyedza kune vatengi.