Tungsten Powder Mugadziri

Product Description

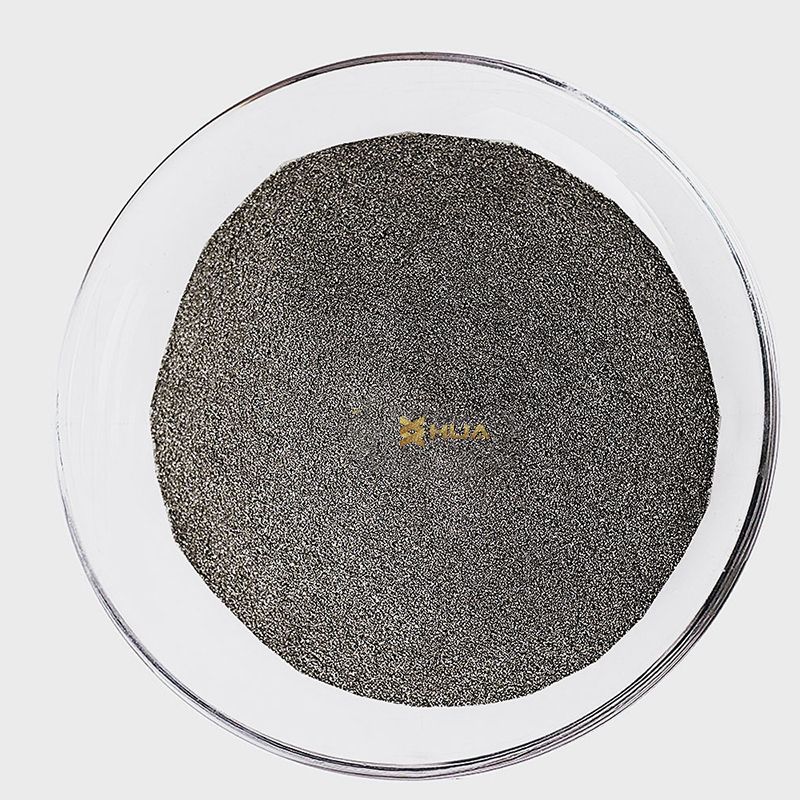

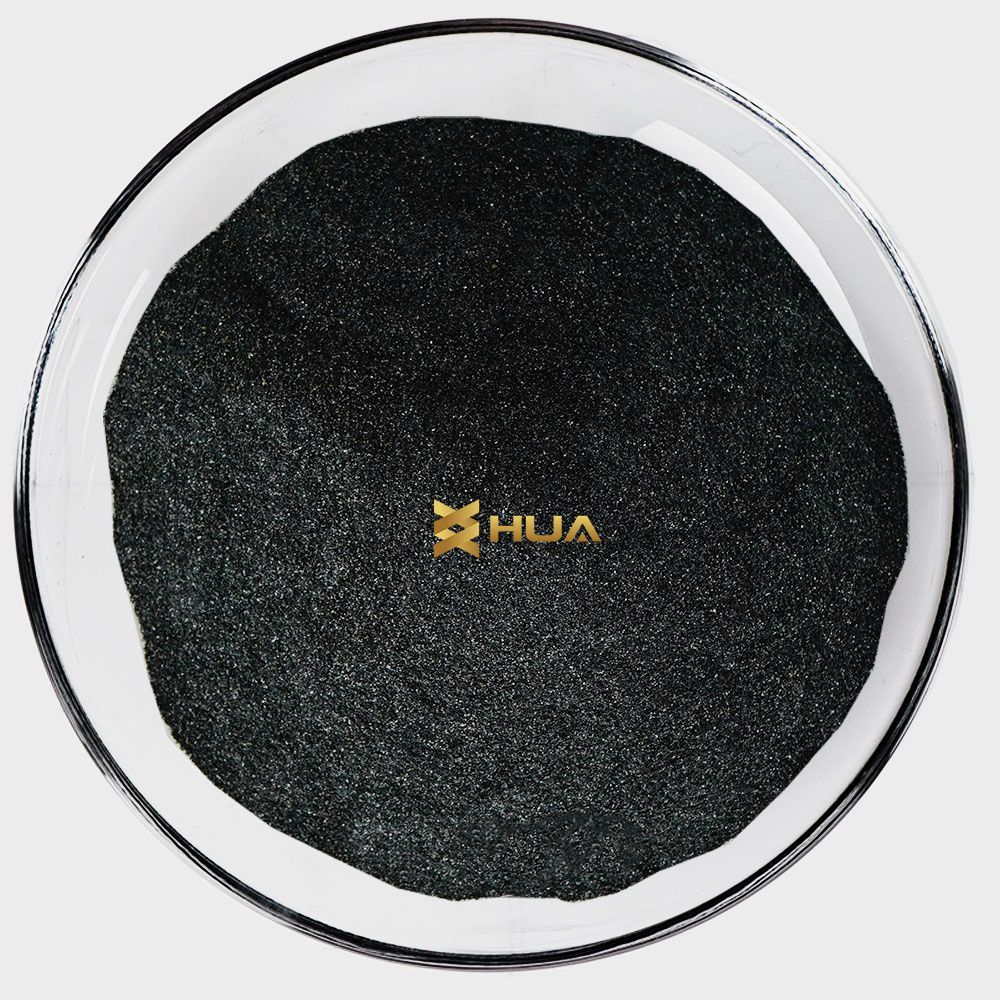

Zvimiro zveSpherical tungsten poda:

Okisijeni yakaderera (<250 ppm)

High sphericity uye spherical degree (> 95%)

Yakakwira liquidity, hapana satellite kana agglomerates bhora

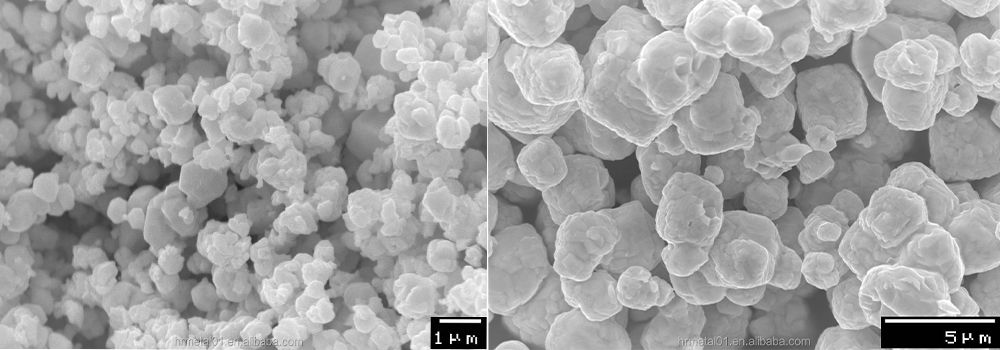

Induced Plasma Maitiro eSpherical tungsten poda:

Yakasarudzika induction plasma process inogona kunge inopfuura makumi maviri emhando dzesimbi uye ceramic zvinhu mu spherical poda, kusanganisira tungsten, molybdenum, tantalum, niobium.

Tsanangudzo

| Tungsten / wolfram hupfu | ||||

| Chemistry/Giredhi | FW-1 | FW-2 | FWP-1 | |

| Zvishoma pane (Max.) | Fe | 0.005 (chikamu saizi ≤ 10um) | 0.03 | 0.03 |

| 0.01 (chidimbu saizi> 10um) | ||||

| Al | 0.001 | 0.004 | 0.006 | |

| Si | 0.002 | 0.006 | 0.01 | |

| Mg | 0.001 | 0.004 | 0.004 | |

| Mn | 0.001 | 0.002 | 0.004 | |

| Ni | 0.003 | 0.004 | 0.005 | |

| Pb | 0.0001 | 0.0005 | 0.0007 | |

| Sn | 0.0003 | 0.0005 | 0.0007 | |

| Cu | 0.0007 | 0.001 | 0.002 | |

| Ca | 0.002 | 0.004 | 0.004 | |

| Mo | 0.005 | 0.01 | 0.01 | |

| P | 0.001 | 0.004 | 0.004 | |

| C | 0.005 | 0.01 | 0.01 | |

| Giredhi | Chinhu Nha | (BET/FSSS) | Okisijeni(%)max |

| Ultrafine zvimedu | ZW02 | >3.0m2/g | 0.7 |

| ZW04 | 2.0-3.0m2/g | 0.5 | |

| Micro-sized particles | ZW06 | 0.5-0.7um | 0.4 |

| ZW07 | 0.6-0.8um | 0.35 | |

| ZW08 | 0.7-0.9um | 0.3 | |

| ZW09 | 0.8-1.0um | 0.25 | |

| ZW10 | 0.9-1.1um | 0.2 | |

| Fine particles | ZW13 | 1.2-1.4um | 0.15 |

| ZW15 | 1.4-1.7um | 0.12 | |

| ZW20 | 1.7-2.2um | 0.08 | |

| Zvimedu zvepakati | ZW25 | 2.0-2.7um | 0.08 |

| ZW30 | 2.7-3.2um | 0.05 | |

| ZW35 | 3.2-3.7um | 0.05 | |

| ZW40 | 3.7-4.3um | 0.05 | |

| Zvimedu zvepakati | ZW45 | 4.2-4.8um | 0.05 |

| ZW50 | 4.2-4.8um | 0.05 | |

| ZW60 | 4.2-4.8um | 0.04 | |

| ZW70 | 4.2-4.8um | 0.04 | |

| Zvimedu zvakakora | ZW80 | 7.5-8.5um | 0.04 |

| ZW90 | 8.5-9.5um | 0.04 | |

| ZW100 | 9-11um | 0.04 | |

| ZW120 | 11-13um | 0.04 | |

| Hunhu hwakakora chidimbu | ZW150 | 13-17um | 0.05 |

| ZW200 | 17-23um | 0.05 | |

| ZW250 | 22-28um | 0.08 | |

| ZW300 | 25-35um | 0.08 | |

| ZW400 | 35-45um | 0.08 | |

| ZW500 | 45-55um | 0.08 |

Quality control system

Huarui ine yakasimba yemhando manejimendi system.Isu tinoyedza zvigadzirwa zvedu kutanga mushure mekunge tapedza kugadzira kwedu, uye tinoyedza zvakare tisati tasvika kwese kutumirwa, kunyangwe sampuli.Uye kana uchida, tinoda kugamuchira wechitatu bato bvunzo.Ehe kana uchida, tinogona kukupa sampuro kwauri kuti uedze.

Hunhu hwedu hwechigadzirwa hunovimbiswa neSichuan Metallurgical Institute uye Guangzhou Institute of Metal Research.Kubatana kwenguva refu navo kunogona kuchengetedza nguva yakawanda yekuyedza kune vatengi.