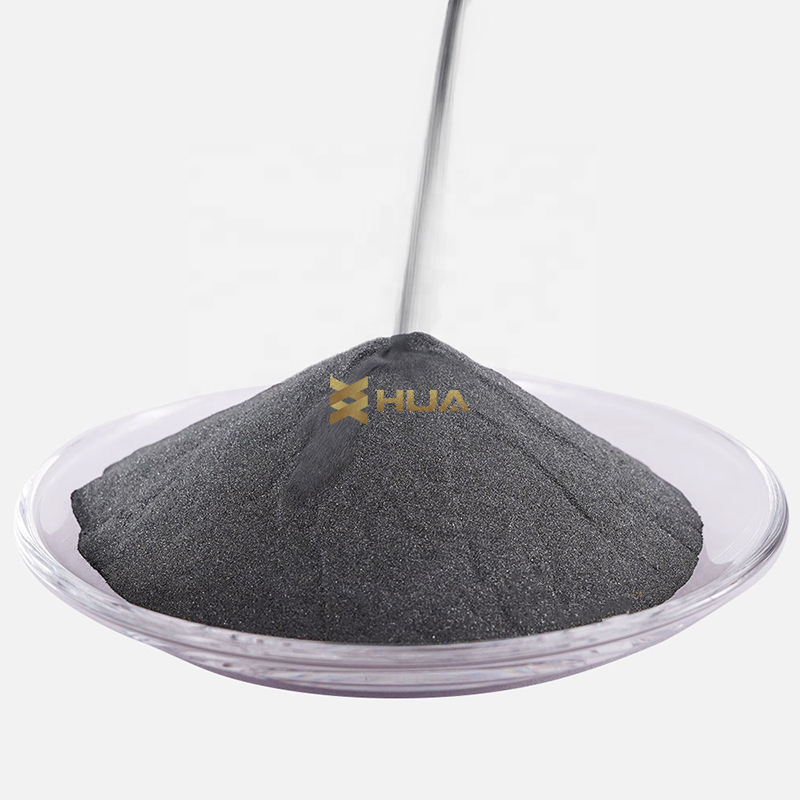

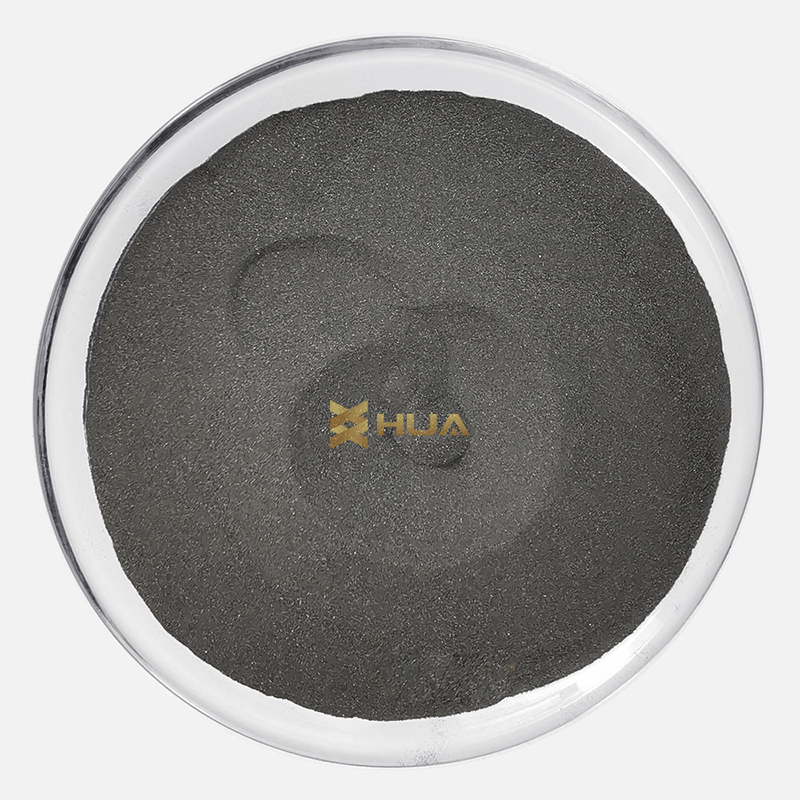

Additive Manufacturing Stainless Steel Powder 316l Powder ye 3d Printing

Product Description

Stainless simbi poda inogadzirwa nemvura atomization process uye ine yakanaka corrosion resistance uye kusimba.Stainless simbi poda ine huwandu hwakawanda hwekushandiswa kwemaindasitiri.

Ipa akasiyana-siyana eStainless simbi hupfu nehukuru hwakasiyana.

Maererano nekushandiswa

1.Hot Isostatic Pressing

2.Metal Injection Molding

3.3D kudhinda

4.Thermal spraying

Maererano nekugadzirwa kwemaitiro

1.Water atomization

2.Water gasi rakasanganiswa atomization

3.Gas atomization

4.Vacuum atomization

Tsanangudzo yezvinyorwa

| Stainess simbi poda kuumbwa% | |||||||||

| Giredhi | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Application

Stainless simbi poda inogona kushandiswa kupisa kupfapfaidza, upfu simbi, upfu metallurgy press sintering (PM), jekiseni molding (MIM) sintering sefa, nezvimwewo, mvura atomization okisijeni zviri mukati.<4000PPM, gasi atomization<1000PPM.

Kubatsira kweHUARUI simbi isina hupfu

●Kunyange kuumbwa kwehupfu, tsvina shoma

●Kutenderera kwepamusoro

●Okisijeni yakaderera

●Kuyerera kwakanaka

● High loose density, high tap density

●Upfu hushoma, hupfu hwesatiraiti hushoma

Quality control system

1.Huarui ine yakasimba yehutano hwehutano hwehutano.Isu tinoyedza zvigadzirwa zvedu kutanga mushure mekunge tapedza kugadzira kwedu, uye tinoyedza zvakare tisati tasvika kwese kutumirwa, kunyangwe sampuli.Uye kana uchida, tinoda kugamuchira wechitatu bato bvunzo.Ehe kana uchida, tinogona kukupa sampuro kwauri kuti uedze.

2.Unhu hwedu hwechigadzirwa hunovimbiswa neSichuan Metallurgical Institute uye Guangzhou Institute of Metal Research.Kubatana kwenguva refu navo kunogona kuchengetedza nguva yakawanda yekuyedza kune vatengi.