Co base cobalt yakavakirwa alloy simbi poda yewelding spraying

Product Description

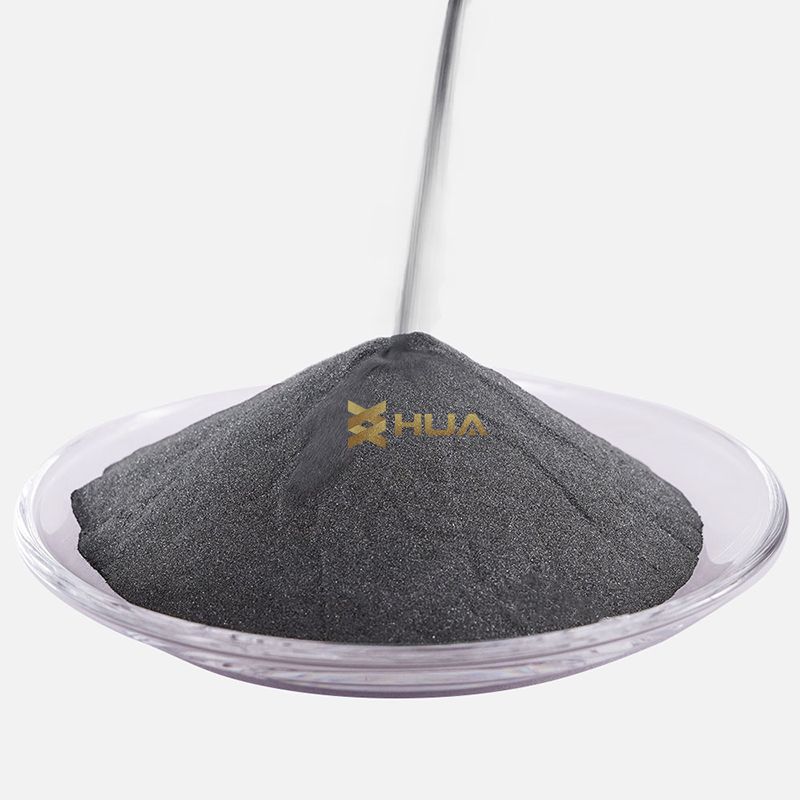

Cobalt based alloy imhando yealloy ine cobalt sechinhu chikuru, ine huwandu hwakati wandei hwenickel, chromium, tungsten uye shoma shoma ye molybdenum, niobium, tantalum, titanium, lanthanum uye zvimwe zvinosanganiswa zvinhu, dzimwe nguva zvine iron.Zvinoenderana nekuumbwa kweiyo alloy, inogona kugadzirwa kuita welding waya, hupfu hwekuomesera pamusoro pepamusoro, kupisa kwemafuta, kupfapfaidza welding uye mamwe maitiro, anogona zvakare kugadzirwa kuita kukanda uye kuforoma zvikamu uye poda metallurgy zvikamu.

Tsanangudzo

| Item | HR-Co1 | HR-Co6 | HR-Co12 | HR-Co21 |

| HRC | 48 | 38 | 42 | 28 |

| C | 2.4 | 1.15 | 1.4 | 0.25 |

| Cr | 30.5 | 29 | 29.5 | 27.5 |

| Si | 1 | 1.1 | 1.45 | 2 |

| W | 12.5 | 4 | 8.25 | 0.15 |

| Fe | 3 | 3 | 3 | 2 |

| Mo | 1 | 1 | 1 | 5.5 |

| Ni | 3 | 3 | 3 | 2.5 |

| Co | Bal | Bal | Bal | Bal |

| Mn | 0.25 | 0.5 | 1 | 1 |

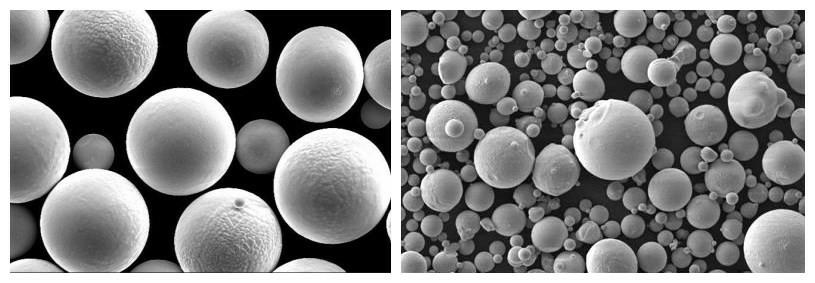

SEM

Application

Cobalt-based alloys ane simba rakanyanya, kumira zvakanaka kuneta kuneta, kupisa kwekupisa uye abrasion, uye yakanaka weldability patembiricha iri pamusoro pe980 ℃.Inokodzera avhiyesheni jet injini, indasitiri gasi turbine, ngarava gasi turbine gwara vane uye nozzle dhizaini vane uye dizeli nozzle nezvimwe.

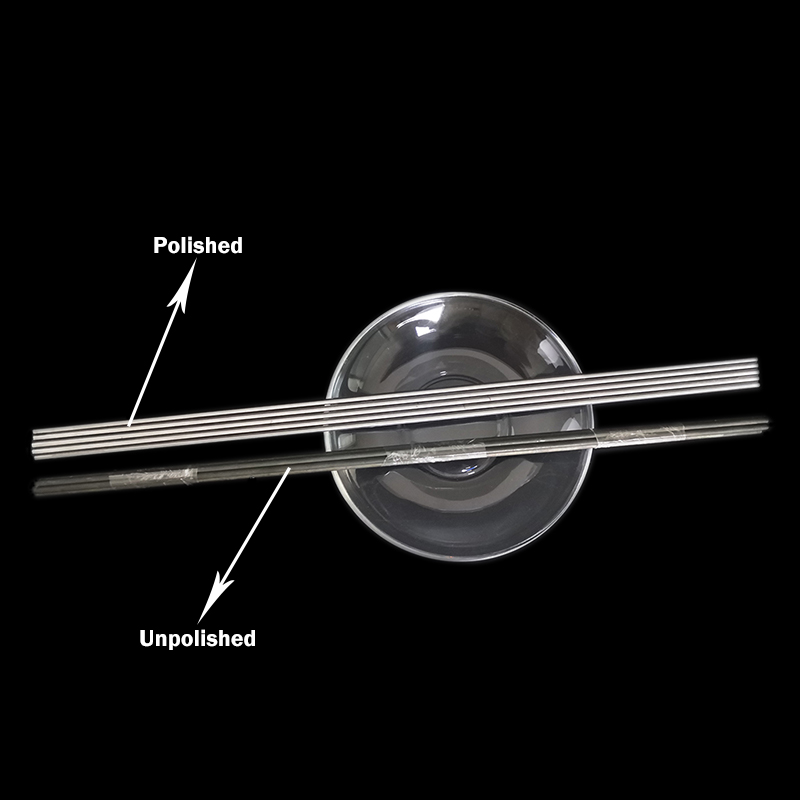

1.Hardfacing

2.Wear-resistant Welding TIG/MIG

3.Thermal spray PTA/HVOF

HUARUI cobalt alloy poda mukana:

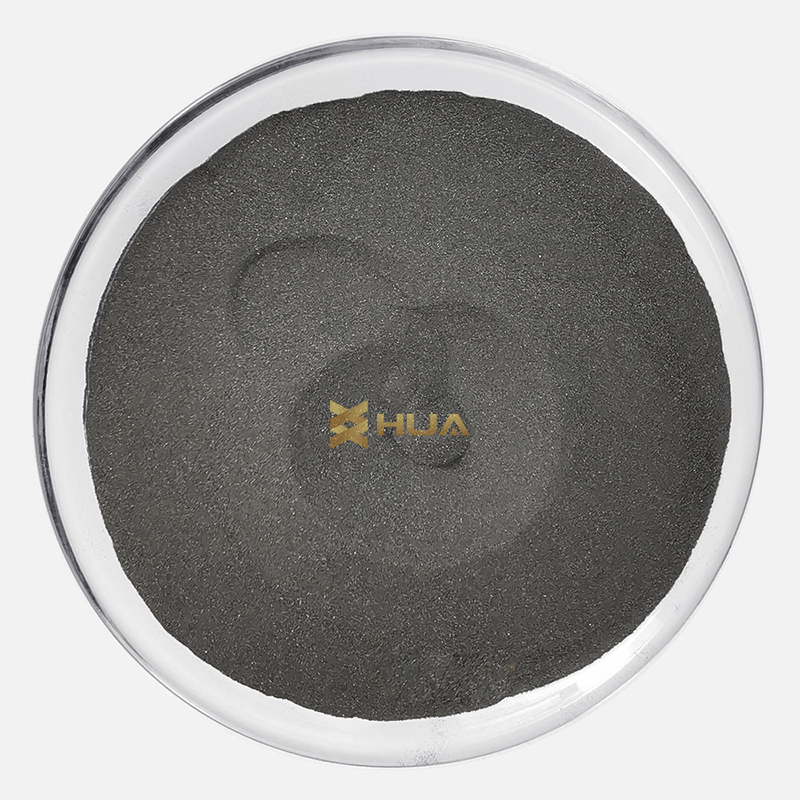

● high sphericity

● yakakwirira yemakemikari inoumba homogeneity

● high inooneka / tapping density

● Low inclusions content

● Okisijeni yakaderera

● Kuyerera kwepamusoro

● Uniform pamusoro ukobvu uye yakaderera porosity