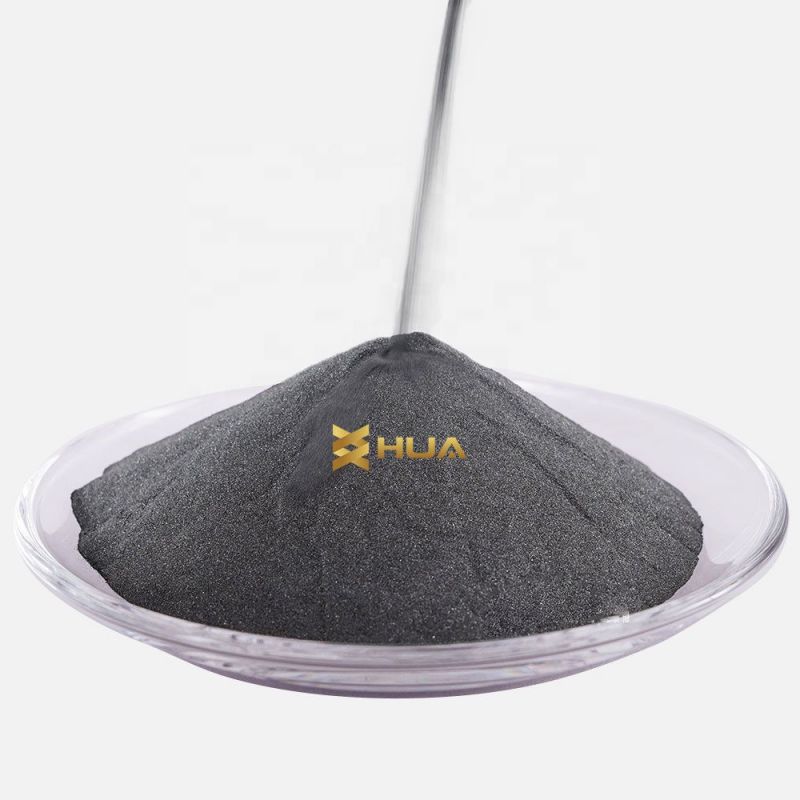

Metal alloy titanium poda ti6al4v poda ye3d kudhinda

Product Description

Ti6Al4V poda inonzi TC4, is an α-β titanium alloy ine simba guru-ku-kurema reshiyo uye yakanakisa corrosion resistance.Ndiyo imwe yeanonyanya kushandiswa titanium alloys uye inoshandiswa zvakanyanya mukudzika-density uye yakanakisa corrosion resistance inofanirwa kune yakadaro aerospace industry uye biomechanical applications (implants uye prostheses).Ti6Al4V inowanzoonekwa se "base" yetitanium industry nekuti ndiyo inonyanya kushandiswa titanium alloy, inopfuura 50% yehuwandu hwetitanium.

TC4 titanium alloy ine yakanakisa corrosion kuramba.Iyo ine nhevedzano yezvakanakira senge yakaderera density, yakakwirira chaiyo simba, yakanaka kuoma, yakanaka weldability uye zvichingodaro.Yakashandiswa mune aerospace, petrochemical, shipbuilding, mota, mishonga uye mamwe maindasitiri.

Tsanangudzo yezvinyorwa

| Titanium nitride poda kuumbwa | |||

| Item | TiN-1 | TiN-2 | TiN-3 |

| Kuchena | >99.0 | >99.5 | >99.9 |

| N | 20.5 | >21.5 | 17.5 |

| C | <0.1 | <0.1 | 0.09 |

| O | <0.8 | <0.5 | 0.3 |

| Fe | 0.35 | <0.2 | 0.25 |

| Density | 5.4g/cm3 | 5.4g/cm3 | 5.4g/cm3 |

| saizi | <1micron 1-3micron | ||

| 3-5micron 45micron | |||

| kuwedzera kwekushisa | (10-6K-1): 9.4 yakasviba / yero poda | ||

Tsanangudzo

| Titanium aluminium alloy (TC4)upfu Zvivakwa | |||||

| Size Range | 0-25um | 0-45um | 15-45um | 45-105um | 75-180um |

| Morphology | Spherical | Spherical | Spherical | Spherical | Spherical |

| PSD-D10 | 7um | 15um | 20um | 53um | 80um |

| PSD-D50 | 15um | 34um | 35um | 72um | 125um |

| PSD-D90 | 24um | 48um | 50um | 105um | 200um |

| Kuyerera kugona | N/A | ≤120S | ≤50S | ≤25S | 23S |

| Apparent Density | 2.10g/cm3 | 2.55g/cm3 | 2.53g/cm3 | 2.56g/cm3 | 2.80g/cm3 |

| Zvemukati Okisijeni(wt%) | O: 0.07-0.11wt%,ASTM chiyero:≤0.13wt% | ||||

Isu tinopawo macustomized services

Welcom inoda COA & yemahara sampuli yeMuedzo

SEM

| Titanium aruminiyamu alloy(TC4)upfu Zvinhu zvikuru: | ||

| Al | V | Ti |

| 5.50-6.75 | 3.50-4.50 | Bal |

Application

1. Laser / electron beam kuwedzera kugadzira (SLM/EBM).

2. upfu metallurgy (PM) uye mamwe maitiro.

3. marudzi akasiyana-siyana e-3D metal printers, kusanganisira Renishaw, Renishaw, Germany EOS (EOSINT M series), Concept Laser, 3D systems uye mamwe laser melting equipment.

4. kugadzirwa kweaerospace parts, Aeroengine Blades nezvimwe zvikamu zvebasa rekugadzirisa.

5. midziyo yekurapa.