alsi10mg poda

Product Description

AlSi10Mg ndeyepamusoro pekuita aluminium-silicon magnesium alloy ine yakanakisa mechanical zvivakwa uye yakanaka yekudziya kugadzikana, iyo inoshandiswa zvakanyanya mukugadzira zvinhu zvakakosha mumhepo inomhanya kwazvo uye indasitiri yemuchadenga.AlSi10Mg alloy ine simba rakawanda, kuoma kwepamusoro uye kunaka kwekusagadzikana, uye inogona kupiswa nekupisa kuti ivandudze maitiro ayo.Iyo alloy inonyanya kushandiswa mukugadzira zvikamu zvinoda simba rakawanda, kusimba uye kuneta kuramba, senge mbabvu dzemapapiro, fuselage zvikamu uye zvikamu zveinjini zvendege inomhanya.Kuenzaniswa nemamwe maaruminiyamu alloys, AlSi10Mg alloy ine yakanaka kupfeka kuramba uye kuneta kuramba, uye inogona kuchengetedza yakagadzikana ma mechanical zvivakwa pakupisa uye kwakaderera.Mukuwedzera, iyo alloy inogonawo kugadzirwa nenzira dzakasiyana dzekugadzirisa, dzakadai sekugaya, kuchera uye kupfugama, izvo zvinogona kugadzirwa nyore nyore muzvikamu zvakasiyana-siyana zvakaoma uye zvimiro.

Tsanangudzo yezvinyorwa

| Aluminium yakavakirwa Alloy Powder | |||||

| Alloy Grades | Alloy Grades | Chemistry | ASTM | ||

| HR10Mg | ZL104 AlSi10Mg | AlSi10Mg CL31Al | Si 9.0-11.0 Fe 0.55max Mn 0.45max Mg 0.2-0.45 | Zn 0.10max Ndi 0.05max Ti 0.15max Al Bal | A03600 |

| HR10Mg | ZL102 AlSi12 | Al Oxide 0.8max Cu 0.30 Fe 0.80 Mg 0.15 | Mn 0.15 Si 11-13 Zn 0.20 Al Bal | ||

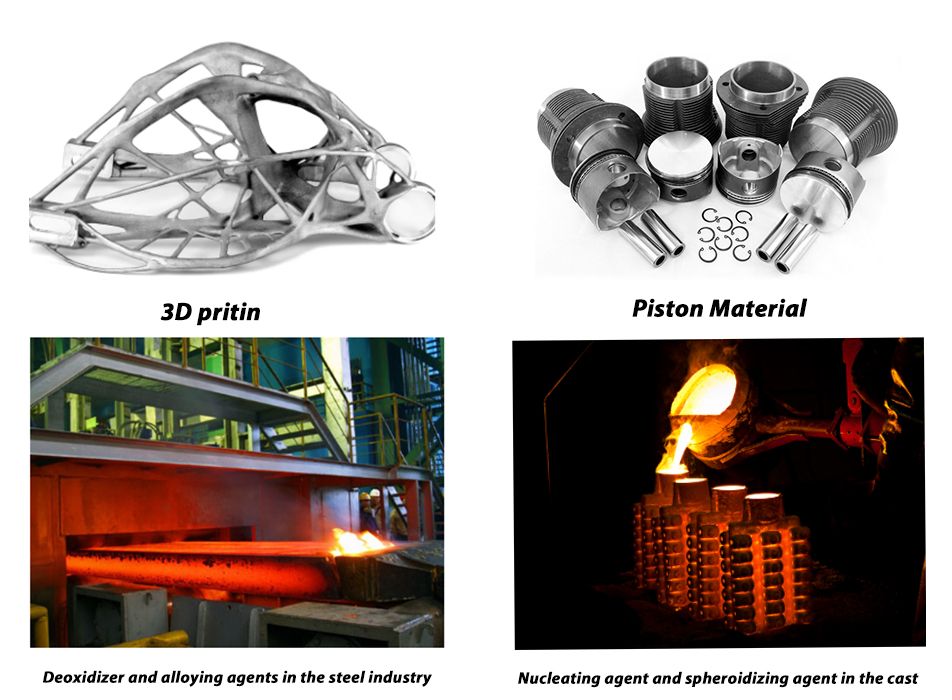

Application

1.Electronic Packaging Materials

2.Se deoxidizer uye alloying agents mumhizha yesimbi.

3.Piston Material

4.Seye nucleating agent uye spheroidizing agent muindasitiri yesimbi yakakandwa.

5.Conductive zvinhu

6.As a reductant mukugadzirwa kweferroalloy.

7.Aluminium brazing

8. 3D kudhinda

Quality control system

Huarui ine yakasimba yemhando manejimendi system.Isu tinoyedza zvigadzirwa zvedu kutanga mushure mekunge tapedza kugadzira kwedu, uye tinoyedza zvakare tisati tasvika kwese kutumirwa, kunyangwe sampuli.Uye kana uchida, tinoda kugamuchira wechitatu bato bvunzo.Ehe kana uchida, tinogona kukupa sampuro kwauri kuti uedze.

Hunhu hwedu hwechigadzirwa hunovimbiswa neSichuan Metallurgical Institute uye Guangzhou Institute of Metal Research.Kubatana kwenguva refu navo kunogona kuchengetedza nguva yakawanda yekuyedza kune vatengi.